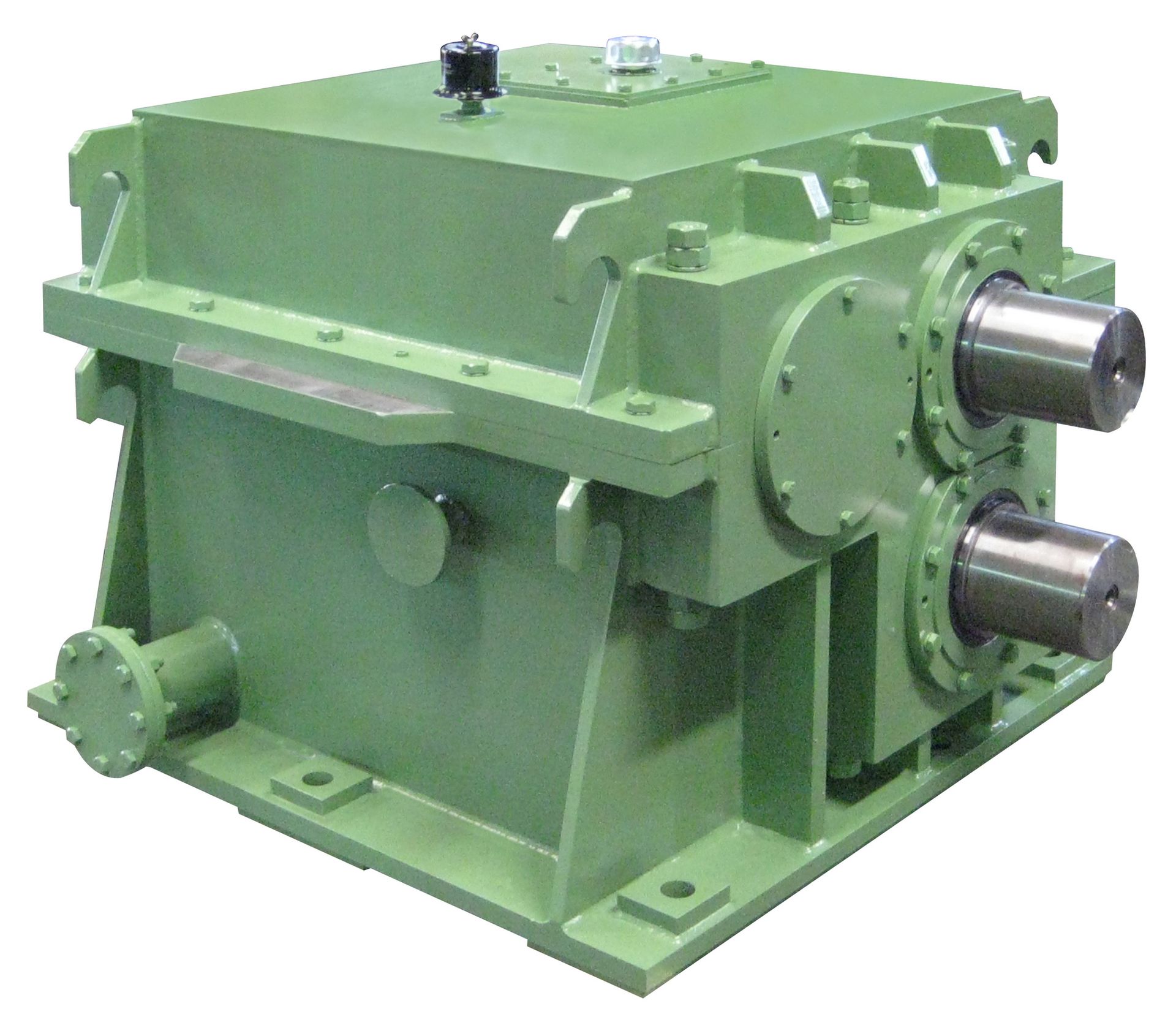

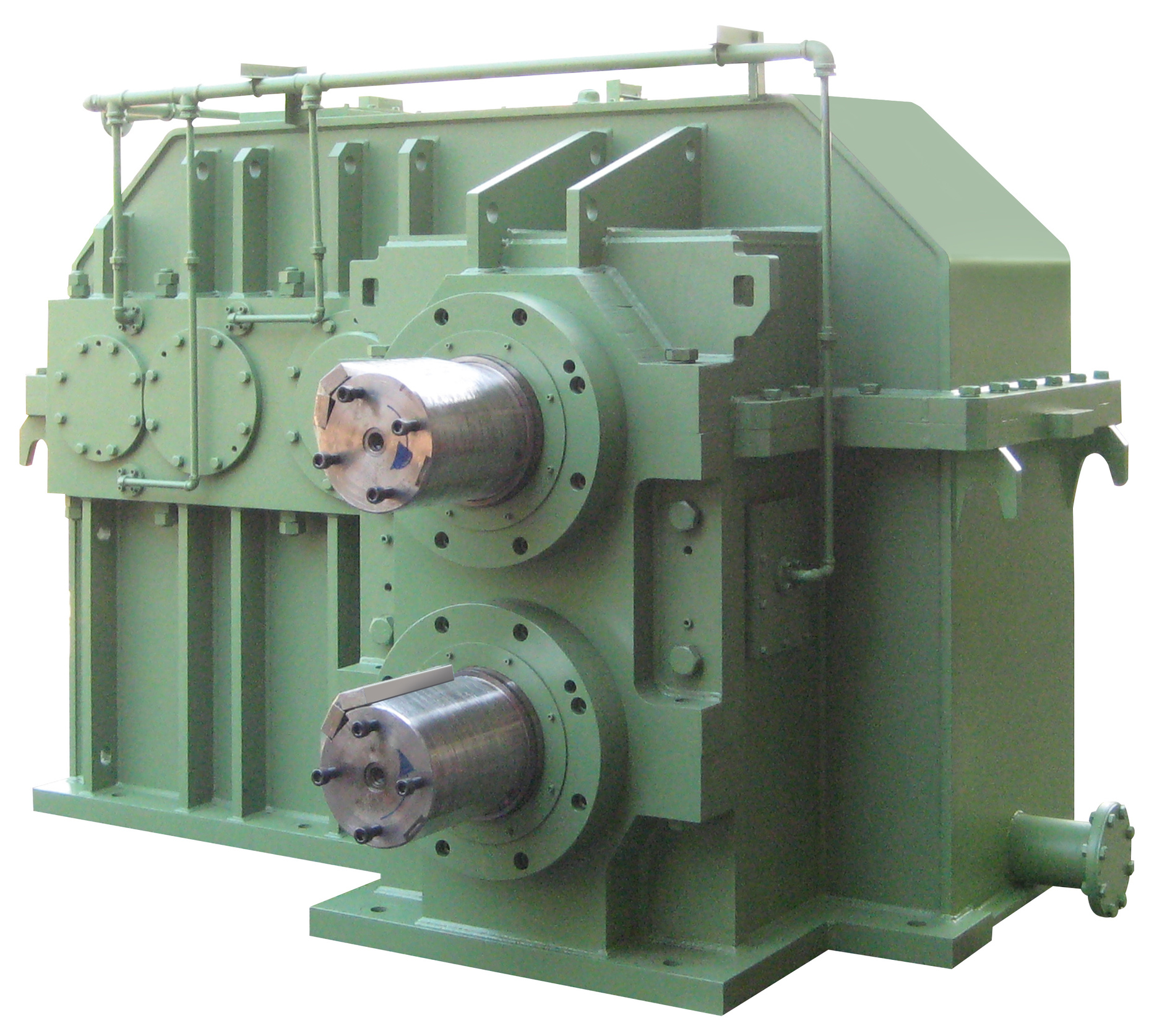

Reference Model

您的動態代碼段將顯示在此處... 顯示此消息是因為您沒有同時提供要使用的過濾器和模板.

The steel industry stands out as a major user of gearboxes and gear reducers due to the sheer scale and intensity of its machinery. Steel manufacturing requires heavy-duty machinery that can provide precise control over speed and power transmission. Gearboxes play a crucial role in adjusting and maintaining the rotational speed and torque, enabling the accurate and efficient production of various steel products such as sheets, bars, beams and tube foaming.

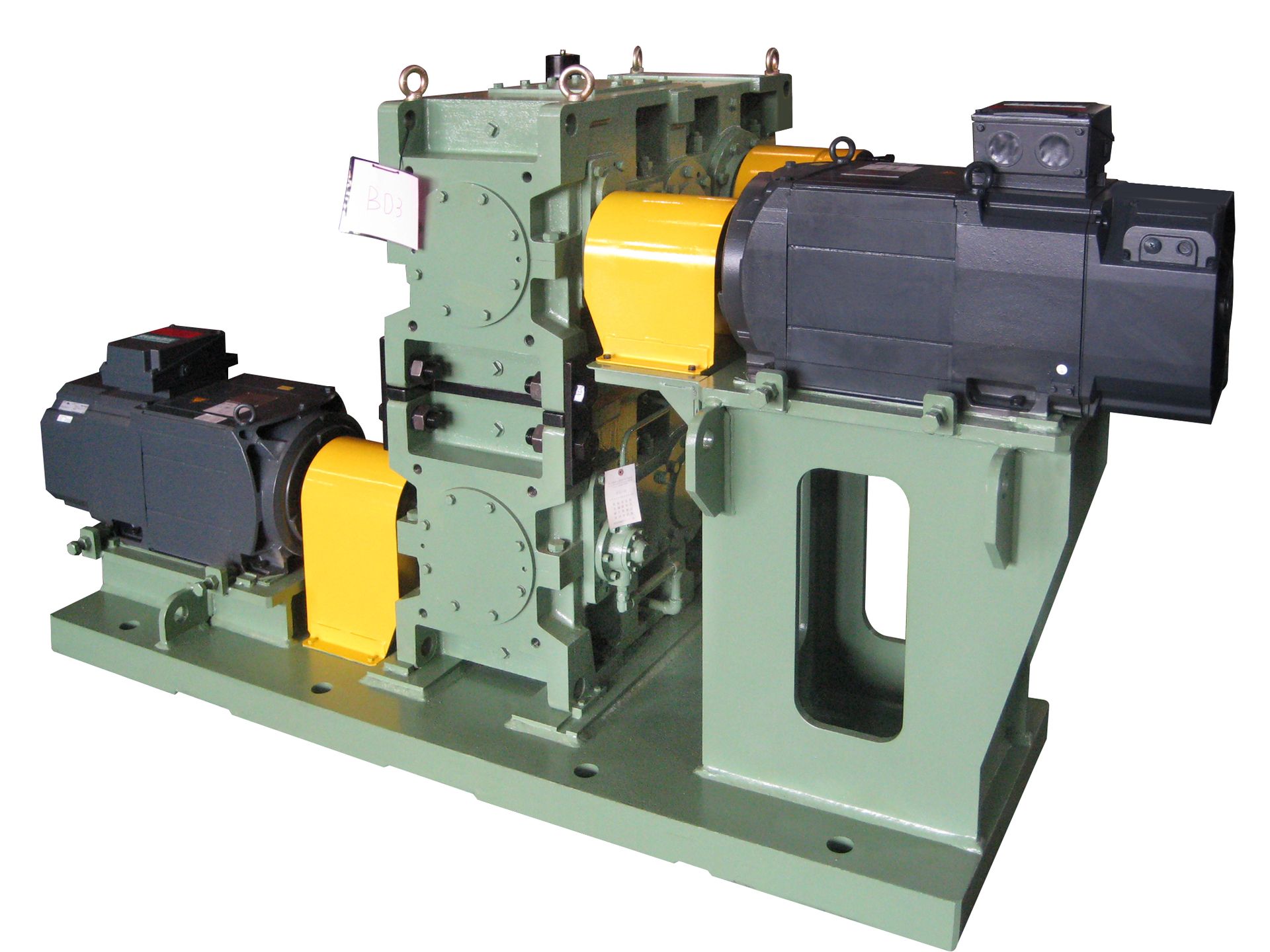

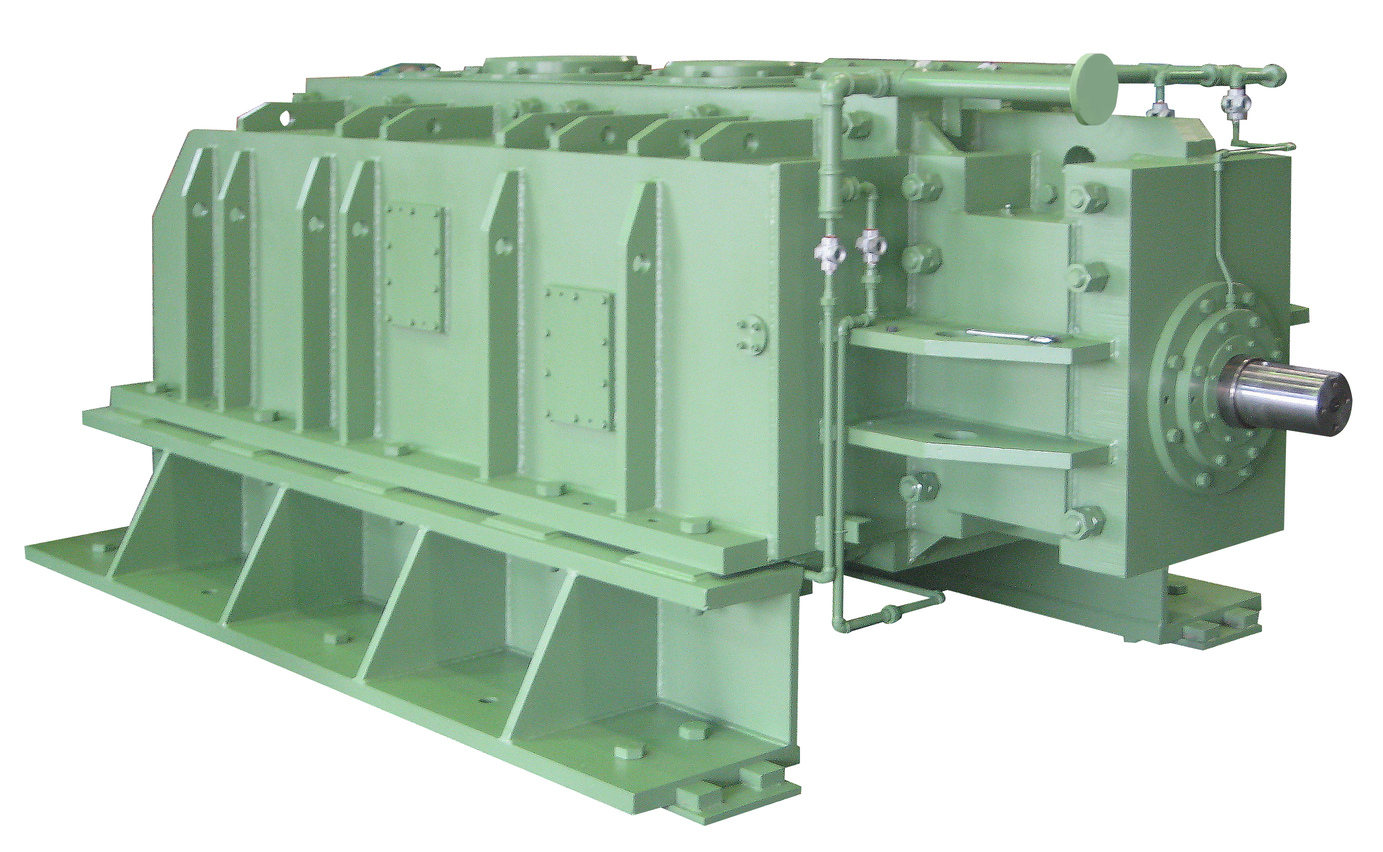

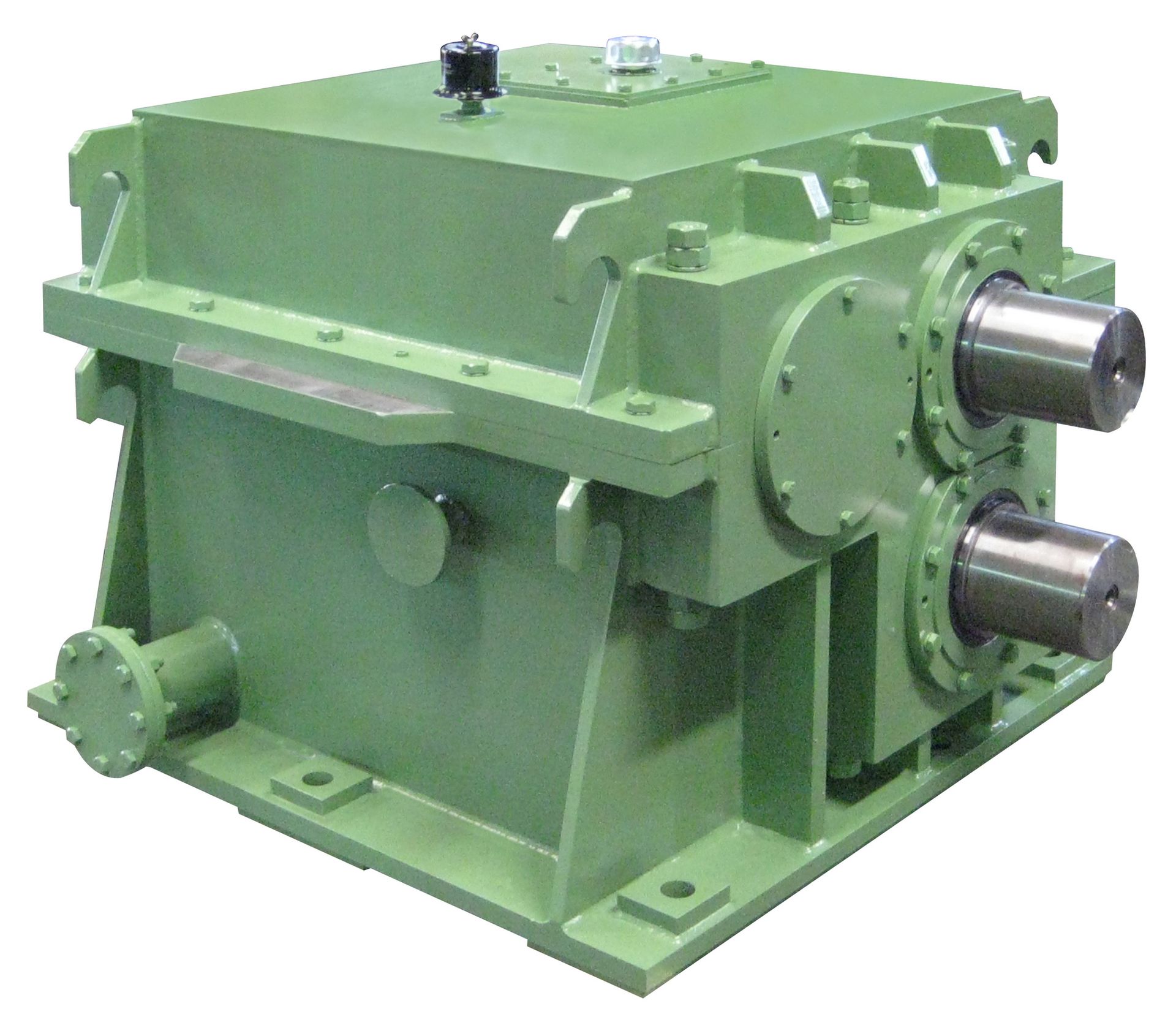

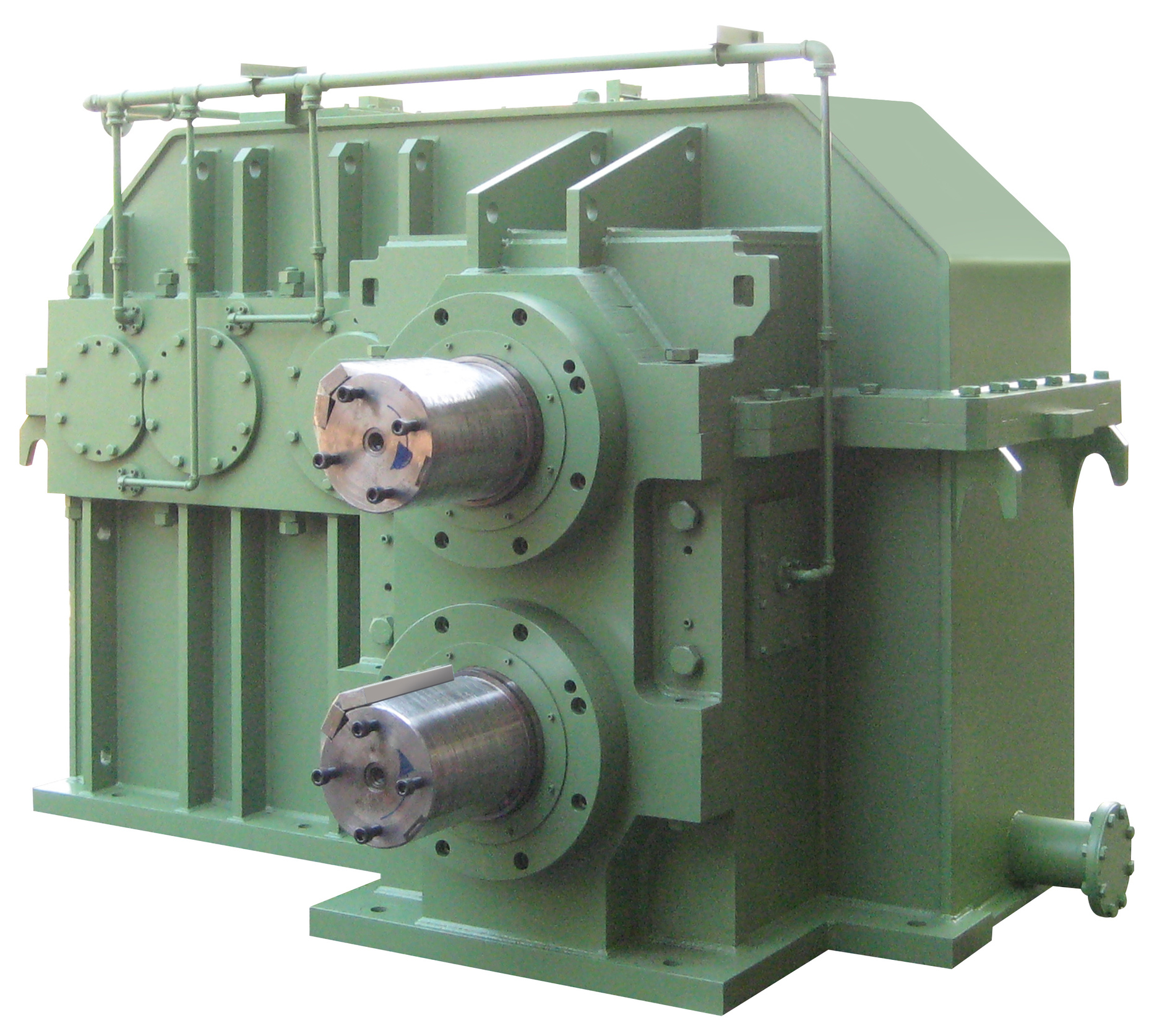

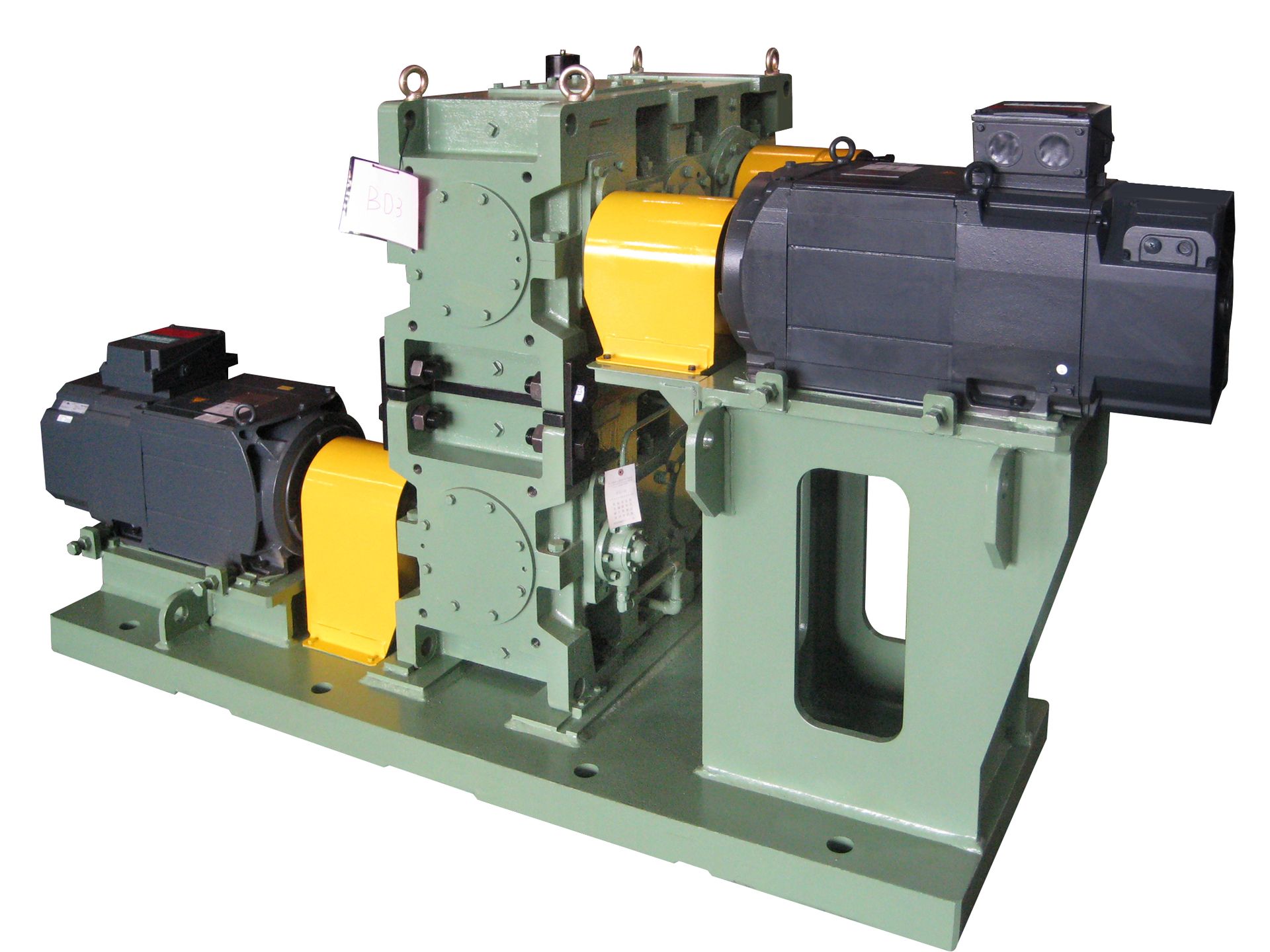

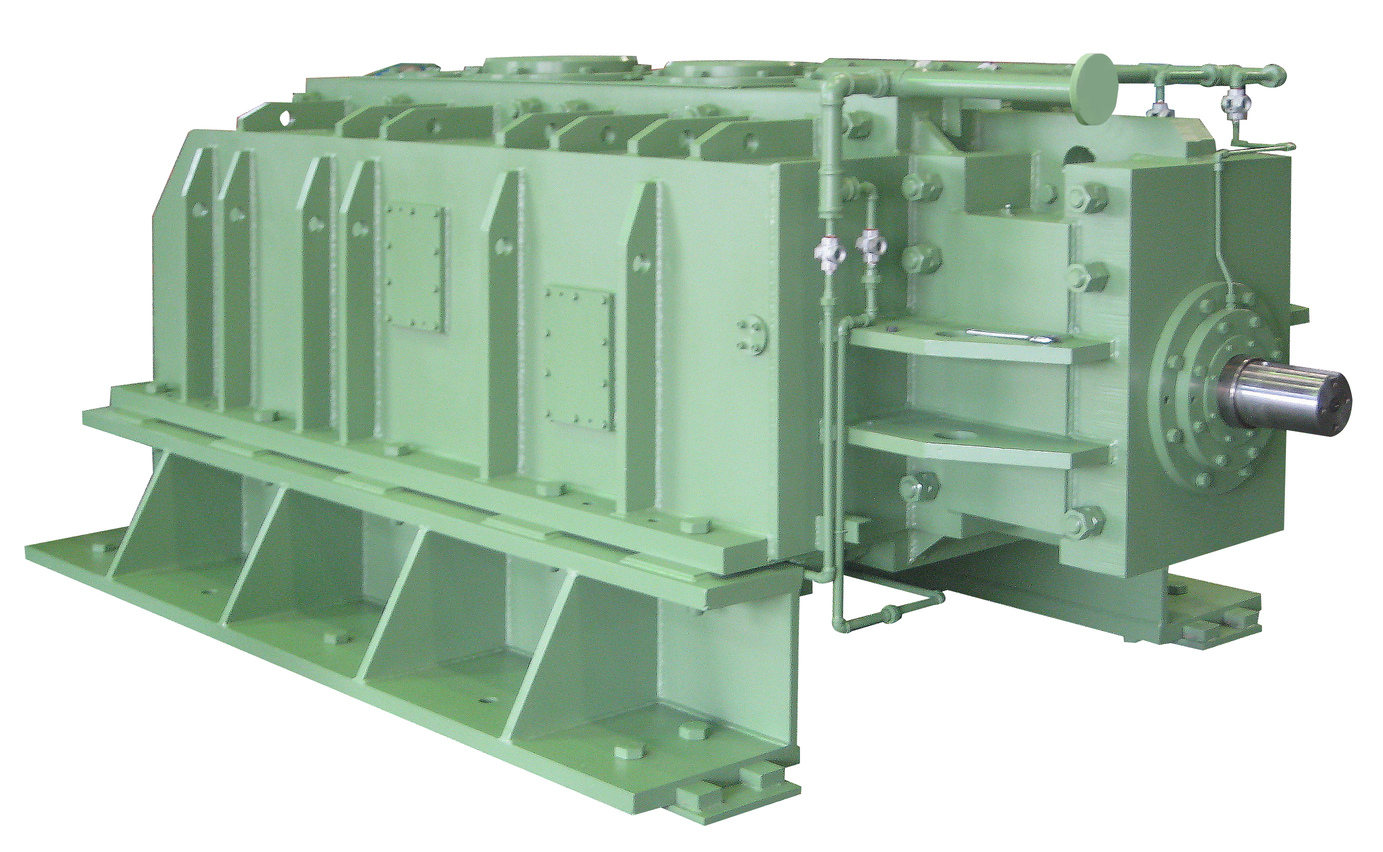

TIEN YI has extensive experience in designing and manufacturing all types of gears and gearboxes used in various steel rolling process, cutting, and forming machines. We offer reliable solutions that meet the high requirements and extreme working conditions of the steel industry.

Various applications of gearboxes in steel industry machinery include:

In all applications, gearboxes must be robust and reliable. Efficient cooling and lubrication effectively dissipate heat and ensure smooth operation over extended periods. Low noise and vibration create a safer and more comfortable working environment, while a compact design optimizes space utilization.

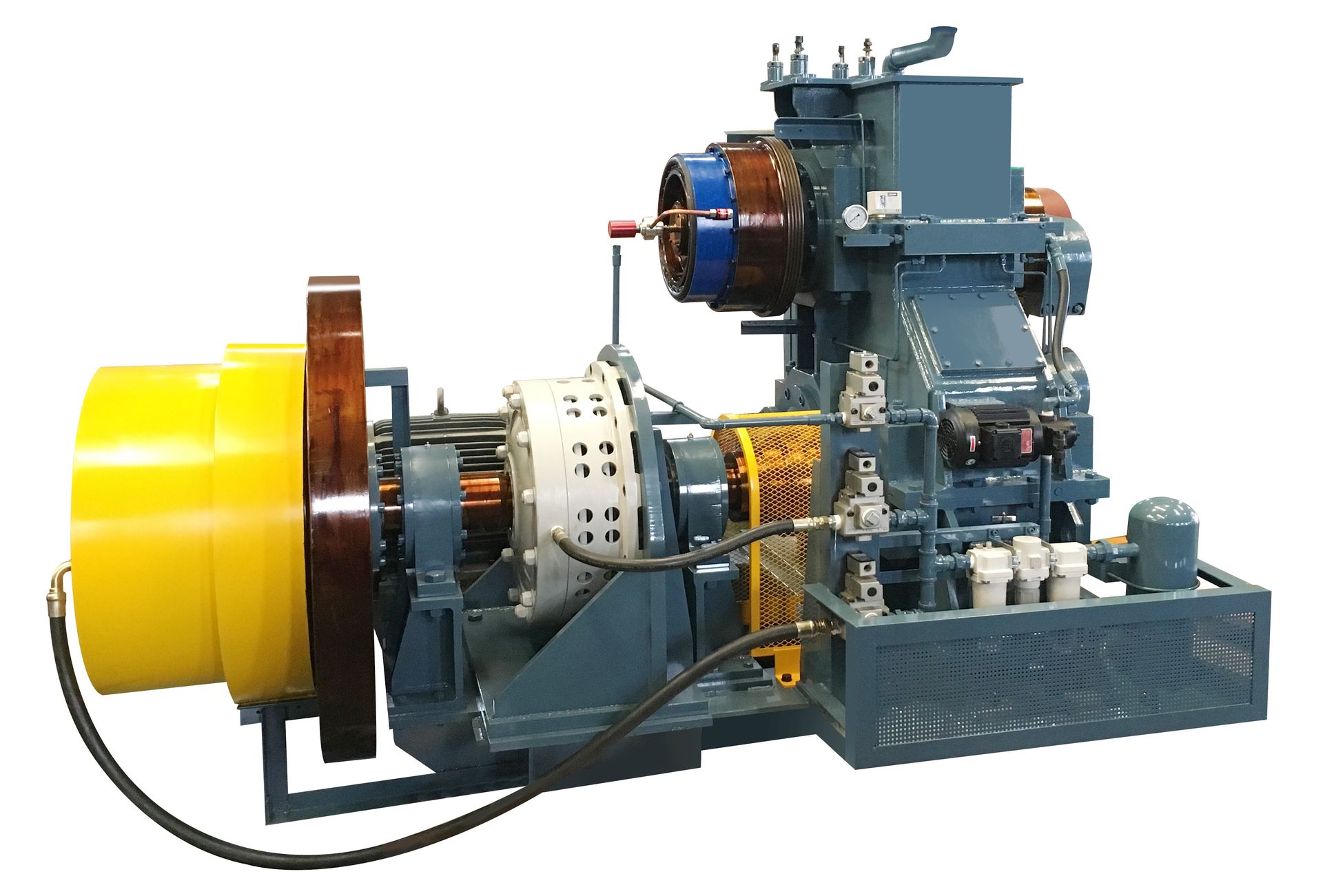

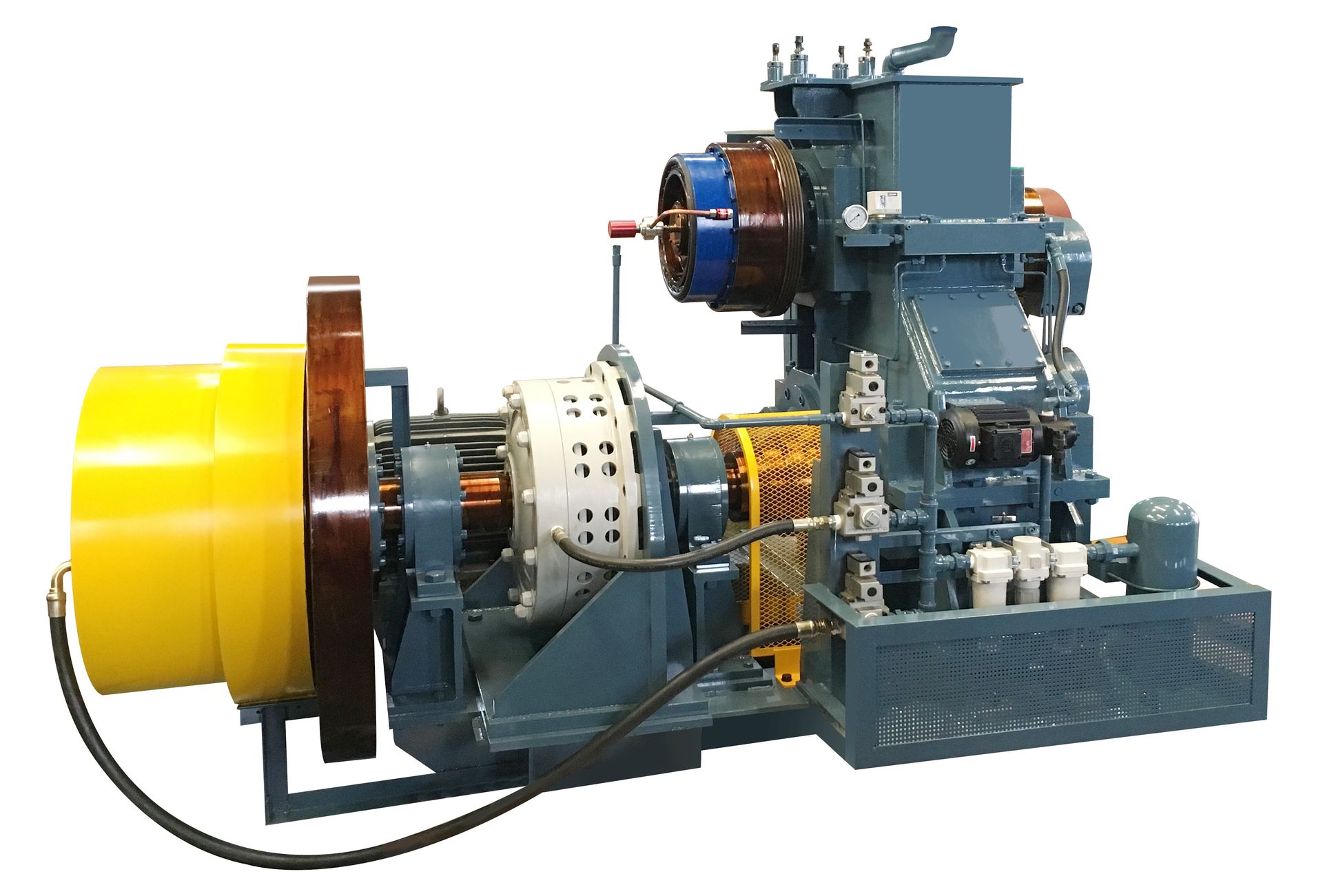

Gear couplings are devices used to connect two rotating shafts, transmit power and torque, and allow for bending and misalignment of the two shafts. Industrial gear couplings are known for their ability to handle high torque transmission and are particularly valuable in heavy-duty applications, such as steel manufacturing, where large machinery and equipment are employed to handle substantial loads.

Steel manufacturing processes often require high rotational speeds. Gear couplings are capable of transmitting torque efficiently at high speeds. They are extremely durability and can withstand extreme temperatures, harsh environments, and heavy loads while operating at high rotational speeds.

The design of gear couplings facilitates easy maintenance and inspection, enabling quick component replacement if necessary. Moreover, these couplings offer additional safety benefits and are less likely to experience severe failures.

Universal joints are commonly used in power transmission industries, where they play a vital role in transmitting rotational motion and torque between shafts at various angles. They enable smooth power transfer while accommodating misalignments during transmission, facilitating the balance of suspension systems.

Features:

A universal joint is a mechanical transmission device that can transmit torque and motion at different angles and directions. It has the following characteristics:

Solutions for power transmission:

TIEN YI, with a rich history dating back to 1974, specializes in producing high-quality OEM/ODM and private-label gearboxes, gear reducers, gear couplings, disc couplings, universal joints, and custom precision gears. As an ISO 9001-2015 certified and AGMA member company, TIEN YI serves a diverse market, encompassing domestic sales, as well as countries in Asia (Japan, China, Malaysia, Indonesia, Philippines, Thailand, Vietnam, India), and the Americas (USA, Mexico, Brazil).

By employing advanced manufacturing techniques, such as precision CNC machining, gear hobbing, heat treatment, and gear profile grinding, utilizing premium-grade materials, and implementing rigorous quality control measures, TIEN YI ensures the production of accurate gear profiles, optimal performance, and exceptional product quality.

Whether you are looking for standard TYGear models like our TK series, TM series, Universal Joint TYL, TYB, & TYBs series, or TYGear Coupling series, or have custom requirements, please contact us for all your gear needs.